You are reading this because you are in the process of exploring and educating yourself about how to get started on a lean journey either for you or for your organization. I’m sure you at this point have read a lot of different articles, found different blogs and even are up to date with the latest lean books.

I’m sure you also have experienced feedback from colleagues or friends that lean is only for manufacturing industries and they don’t get the connection to lean product development. Don’t give up - I have been there and I still have to explain that lean methods are an excellent tool to improve efficiency, define and maximize customer value, share knowledge, identify value stream and much more. Lean also fits in with many industries like accounting, healthcare, education, food service it’s all about continuous improvement whatever the industry. .

MY LEAN JOURNEY?

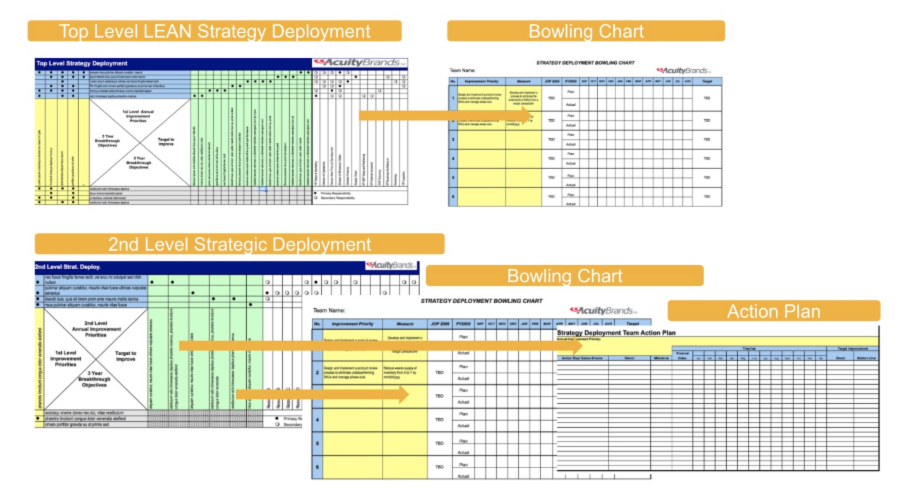

There are many different options and ways to begin a lean journey for you or for your organization - and what is the best way? That depends, for me it started with a corporate decision when I worked for a huge manufacturing company. A lean strategy deployment was rolled out and a consulting firm was hired to implement a defined lean program this was deployed through educating and training the entire corporation. It started with a top level lean strategy deployment supported with a bowling chart together with action plans, this was from the corporate level to the functional level - everybody was involved. Each team got trained in 5S, Value Stream Mapping, KPI dashboard and the biggest learning was if you want to improve you must be able to measure it. It was a whole new way of thinking for the corporation and the approach was more headed to lean manufacturing instead of lean continuous improvement and knowledge sharing, this gave some challenges in a few departments but we all learned together and started to be more data driven. I had a few eye openings and this provided opportunities to improvement of existing processes within the product development process which resulted in a reduced product cycle time from 9 to 6 months.

Next stepping stone in my lean journey was that I got introduced to the LPPDE organization. I attended my first LPPDE conference, where I met other lean practitioners and ambassadors, his was really inspiring and when I won for the best A3 report presentation it showed where my passion lies.

I got inspired by listening to real challenges from real companies and then hear and see how it was solved and implemented with a continuous improvement angle approach. With this new knowledge and experience, I was responsible for leading corporate strategies to define and implement lean thinking - one of the results was a 20% reduction in development time accomplished through a systematic redesign of developing processes that captured knowledge in early development and eliminated problems in late development. I facilitated local and cross-functional continuous improvement activities along driving culture change. Another lean initiative I drove was to implement a visual R&D’s performance management dashboard, this increased the predictability and the ability to deliver more projects with the same resources due to this specific visual lean tracking tool.

LEAN WAY OF THINKING AND WORKING

Hereafter lean became my way of thinking and working, I have always used continuously improvement as my pillar and I have been able to increase productivity by improving product development processes and streamlined information flow using visualization, collaboration and transparency. A visual one-pager has always been my “‘go-to’ tool either in form of a product brief, development process, roadmap or a competitor landscape and the one-pager has been a great way to effectively communicate to my team or throughout the organization. Visual information is easier to digest so when communication through an organization take advantage of this - in fact the human brain process images 60,000 times faster than text and if you look around in your day-to-day surroundings there is a lot of visual information e.g. computer icons, traffic signs, dashboards and more.

FAIL FAST

Don’t be afraid to fail - the biggest learning when working with lean for so many years is fail fast together with building a positive atmosphere in the organization which tolerates mistakes. When improving a process it is never a “one take” it takes several improvement iterations, I have examples of some cases where it took five or eight iterations. You learn everyday and you learn while doing so it is important to stop and do reflections or lessons learned on a process and then create a new iteration of the process.

The faster you learn the faster you can optimize the process which will result in a quick and responsive process and parallel you will build a culture of continuous improvement within your organization. A long by failing fast you must be data driven, if you don’t have the the data you are only left with opinions and believe me you want decisions based on data not on opinions.

WHY ATTEND LPPDE WORKSHOP AND CONFERENCE

In today’s world efficiency has a big impact on the company's profit and companies are facing enormous challenges to stay competitive. LPPDE offers exchanging learnings and knowledge from different industries and I have used this as a boost where I can jump-start my lean efforts within my own organization to drive efficiency. I have attended several LPPDE conferences and I have also been a conference speaker which made me able to share my lean knowledge and become a lean ambassadors where I have motivated others to either begin their lean journey or get inspired from my lean activities and results.

Lean applies in every business and every process, so start your lean journey by attending a LPPDE conference, it’s a great lean network where there is room for exchanging learnings and knowledge together with the speakers and attendees. LPPDE offers workshops and conference both in North America and in Europe - check it out here.