What is Lean PD?

Lean Product Development is a generic term for applying “Lean Thinking” onto the product and process development context. Lean Thinking was first written down by J. Womack, who interpreted the backgrounds of the success of, amongst others, Toyota.

Lean Thinking is more of a cultural aspect than a set of methods and tools. It, therefore, includes key principles and key behaviors to achieve a state of continuous improvement as a starting point and methods and tools as an effect thereof. Many lean practitioners, at the start, focus on the tools and methods and only later recognize the need and value of the key principles and behaviors.

Lean started out as a method to improve efficiency and effectiveness in manufacturing. Although you can apply the same key principles and key behaviors to the context of product development, the methods and tools are harder to translate. Lean Product Development has its own set of methods and tools and its own set of challenges related to implementation.

Lean Product Development starters, practitioners and experts get together at the Lean Product and Process Development Exchange events to share their insights, such that we continue to develop the framework of Lean in Product Development together, containing for example:

Methods to grow and improve understanding of customer value

-

Cadence, pull, & flow

-

Set-based development

-

Reusable knowledge

-

Visual management

-

Entrepreneurial system designer

-

Teams of responsible experts

Excerpts from and LPPDE Blog post:

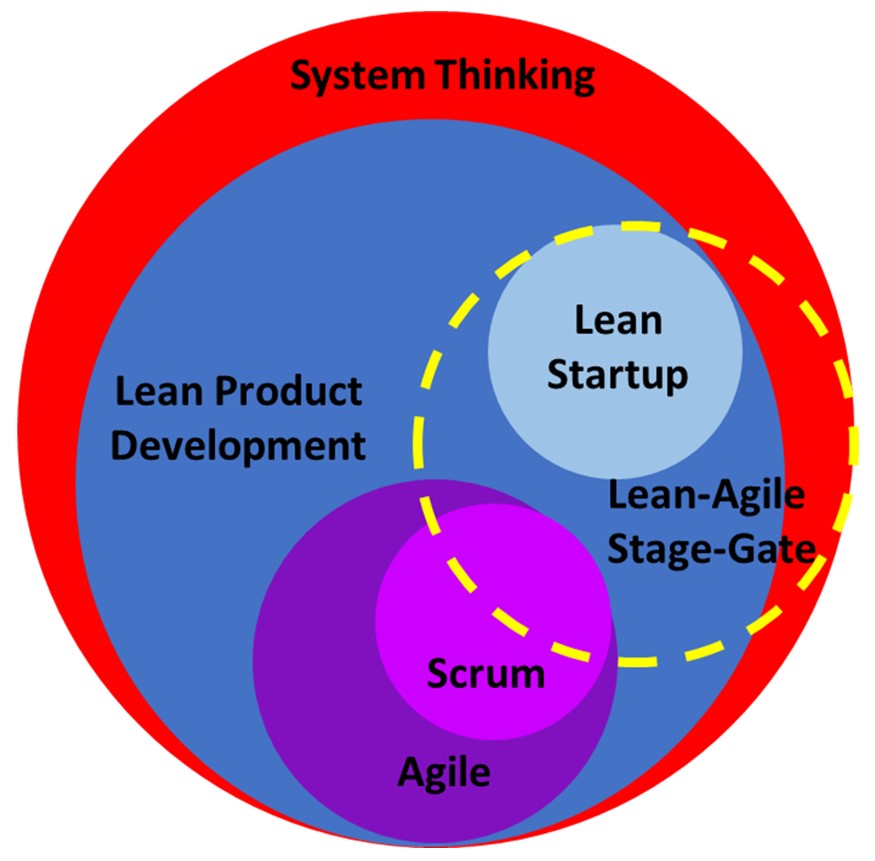

As illustrated in the accompanying Venn diagram, a Systems Thinking framework is at the center and encompasses all other methodologies. Lean Product Development falls within Systems Thinking and encompasses the other remaining methodologies. Scrum falls within Agile, which is itself within Lean Product Development. Finally, Lean Startup is separate from Agile but falls fully within Lean Product Development. The Lean-Agile-Stage-Gate framework also falls completely within Systems Thinking and overlaps with Lean Product Development.