Program

Time Zone: Greenwich Mean Time (GMT)

March 9, 2023

Thursday - Virtual Conference

Exchange in a Digital World!

Exchange Following the spirit of Lean Product & Process Development EXCHANGE there will be good possibilities to Exchange knowledge with other attendees as well as with the speakers.

After each presentation, we have a session +Reflections and interaction where you will reflect and interact on the learnings from the presenter.

We end the virtual LPPDE with some final reflections and remarks and hope the Exchange will continue on our LinkedIn site

International Thought Leaders

Joe Justice

Authored Scrum Master (book), created eXtreme Manufacturing, founded WIKISPEED, Agile Business Institute

Christer Lundh

Aufero

Ingela Hofverberg

Atlas Antibodies

Andreas Dörken

Argo

Half-day virtual summit, only 99 € + VAT 24% if applicable.

Pay for 3 virtual summits (recording or live), only 250 € + VAT 24% if applicable

Pay for Full Year (10 virtual summits, Live and Recordings), only 700 € + VAT 24% if applicable

Registrations through Lean Association of Finland:

Thursday, March 9, 2023 Virtual Conference

1:05pm GMT

Microsoft Teams Conference

"Extreme manufacturing” - Scrum for hardware

Joe Justice

Authored Scrum Master (book), created eXtreme Manufacturing, founded WIKISPEED, Agile Business Institute

1:45pm GMT

Break

1:50PM GMT

Microsoft Teams Conference

Extreme Ownership

Christer Lundh

Aufero

2:30pm GMT

Breakout rooms - Reflections and interaction

2:40pm GMT

Reflections and questions to the speakers

2:50pm GMT

Break

3:05PM GMT

Microsoft Teams Conference

Lean as an Integrated Part of your Business System

Ingela Hofverberg

Atlas Antibodies

3:45pm GMT

Short Break

3:50PM GMT

Microsoft Teams Conference

The Lean Machine 7+1, coaching and the need of skilled help to

succeed

Andreas Dörken

Argo

4:30pm GMT

Breakout rooms - Reflections and interactions

4:40pm GMT

Reflections and questions to the speaker

5:00pm GMT

End

We are bringing our 2023 speakers to you!

Download the ProgramPresentation Abstracts and Presenter Bios

Peter Palmér, LPPDE and Juha Tammi, Lean Association of Finland

Peter and Juha represent the two organization who organize these virtual online events and will moderate the Virtual Summit.

What does “Digital self management” Taking out entropy mean? Joe will explain this and more. It is all about enabling 80% of people work on the product all the time. Eliminating waiting on decisions. Quality assuring every change and every car. All people are trusted and empowered. Joe will share his experience and lot´s of examples from his bank of knowledge.

Joe Justice, Authored Scrum Master (book), created eXtreme Manufacturing, founded WIKISPEED, Agile Business Institute – “Extreme manufacturing” – Scrum for hardware

“Extreme manufacturing” Scrum for hardware? Benefits establishing capability to be able to make builds instantly. To get instant feedback on hypothesis through small experiments. Builds and experiment are the transition cost driving the total product development cost (time).

Digital self-management - taking out entropy. Joe will talk about the system that enables 80% of the people to work on the product all the time. How Tesla eliminates waiting on decisions at the same time as the quality is assured in every change and every car. All people are trusted and empowered and work towards the same objective, every day.

Joe Justice is author of Scrum Master, published in 7 languages. Joe has worked with Bill Gates, the leadership team at Amazon, and operated the Agile program at Tesla for Elon Musk. Joe founded WIKISPEED which became an example of automotive design and production speed in a fun, egalitarian culture. Joe enjoys collaborating as a board member, writing, teaching, and running companies to make a good future arrive faster.

Joe works globally as an interim executive for Scrum in Hardware, bringing multinational companies twice the work in half the time. His teams have held 3 world records. He is a TEDx speaker, guest lecturer at both MIT and Oxford University in England, featured in Forbes 5 times to date including as owner of a “Company to watch” by Forbes Billionaire Club, cited in more than 5 business paperbacks and hardcovers, the subject of a Discovery Channel mini-documentary for his work creating the discipline Scrum in Hardware while working directly with the co-creator of Scrum, Dr. Jeff Sutherland.

Joe has worked with all of the top 3 military and defense contractors, autonomous and smart road technologies, ultra-lightweight structures, guest lectured at UC Berkeley, MIT, on behalf of Carnegie Melon, CU Denver, The University of Washington, spoken at Google, Microsoft, Zynga, Lockheed Martin, HP Labs, The Royal Bank of Canada, Pictet bank, and others. Joe’s work has been featured in Forbes, Harvard Business Review, CNN Money, the Discovery Channel, and others.

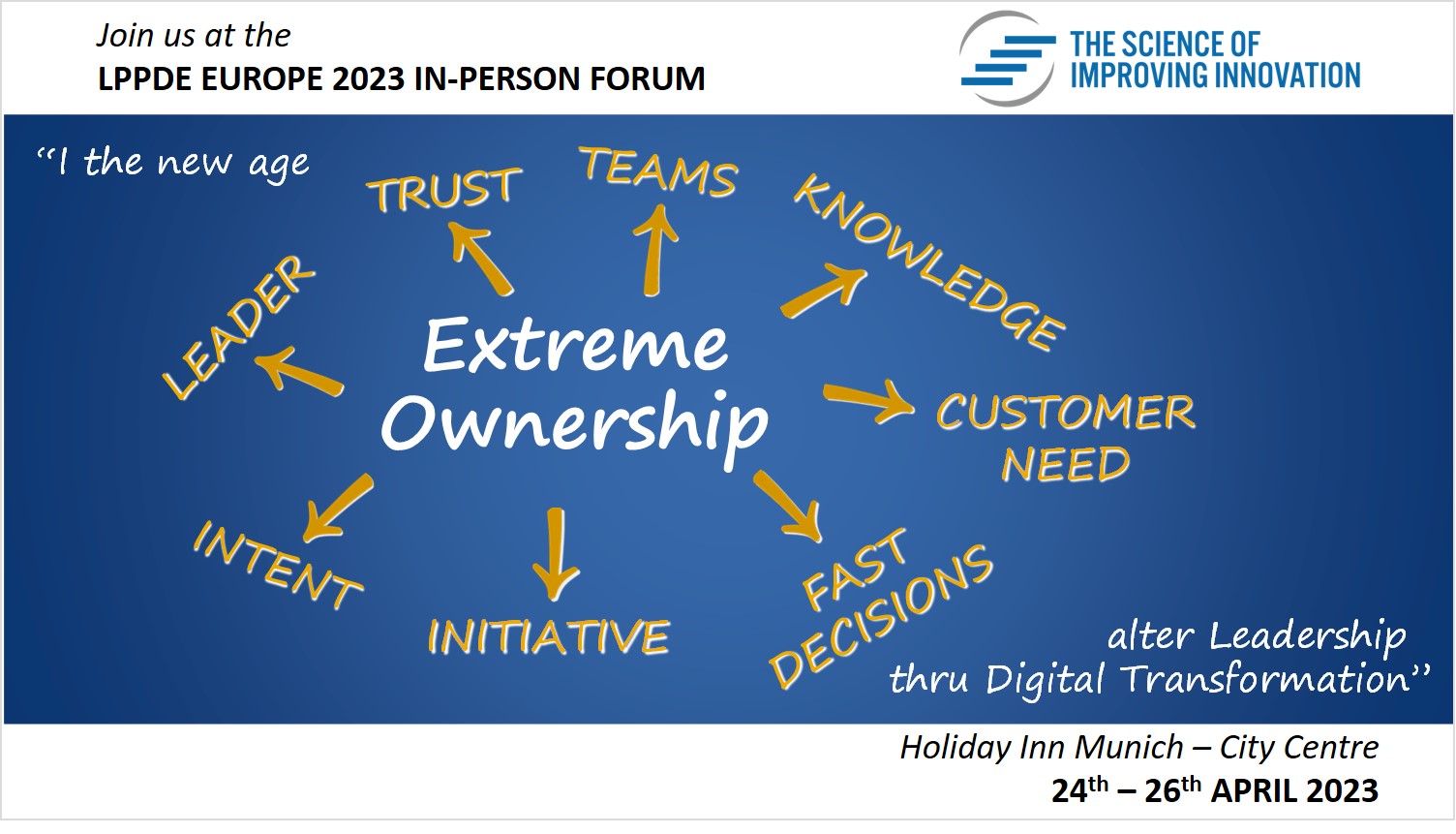

Christer Lundh, Founder and President at AUFERO – Extreme Ownership

The speed and pace of the global operating environment is only getting faster. Leaders and teams that win on any challenge, take “Extreme Ownership” of their continuous improvement while being agile. The effects of making faster decisions, based on just made learnings through customer collaborations, are both aligned to where the future unfolds and are cumulative.

Today’s fastest developing companies have taken the Lean Agile principle of “Test First” to a much higher-level, using machine learning, artificial intelligence and automated testing. Teams are trusted, based on their learnings they can make fast decisions. This embodies; looks at the future, small known errors and large positive gains (opportunities), little understanding is necessary, just rationalizing in comparing two outcomes, exercising and deploying the better option at once.

Christer Lundh has a long and deep understanding of lean product development. Over the past fifteen years, in different leadership positions, he has effectively implemented, and applied product development processes based on Flow and Knowledge Based Development (KBD) at several companies.

To empower people, Christer has successfully adapted development teams around ‘Function / Value’ recognized by customers. Small cross-disciplinary Function Teams, applying Cadence and Flow on two-to-three-weeks takt, using Kanban Flow Boards and Daily Stand-up. And training and mentoring leaders and engineers, on the job training, of A3 process for problem solving / gap closing.

Christer has worked in lean set-up as Entrepreneurial System Designer leading a start-up. With speed and focus, rapid and valuable customer feedback and great sense of urgency, the development teams swiftly improved on every new prototype. Enabled teams to learn about customers’ true needs. With present leadership, challenging targets and empower of people, teams quantify and make gaps visible. To see–transparency–boost motivation. Applying “homing,” with multiple quantified countermeasures, teams together close their gaps, and the best – them owning the solutions.

Ingela Hofverberg, Chief Transformation & Quality Officer at Atlas Antibodies – Lean as an Integrated Part of your Business System

Having practiced Lean for more than 15 years in different industries, countries and environments, it still strikes me how something that should be so easy and based on common sense can be so hard. One of the most common mistakes in implementing Lean is that we take the copy paste approach where the methodology is taken out of its context and applied in a different one. What we should be doing is making sure we understand the problem we are trying to fix, the principles behind the method that can help us to solve the problem and then adapt the method so that it fits into the environment where we are trying to apply it. Having been in the vehicle production industry I have seen this multiple times when methods and tools are being lifted from a production environment into a service or admin environment – very seldom is this a success story. Lean cannot be implemented as a standalone structure

Ingela Hofverberg is a highly experienced, driven, and passionate leader with more than 15 years of working with business transformation. Ingela has designed and implemented management systems and structures founded on Lean principles and values in various different areas.

Andreas Doerken, Partner & SVP at Argo – The Lean Machine 7+1, coaching and the need of skilled help to succeed

Andreas has worked closely with Dantar Oosterwal and continued to develop their Product Development model 7+1. A central part in this Lean Product and Process Development system is Set Based Thinking. Andreas will walk us through the true Fundamentals of the Lean Machine and share his experience on coaching and the need of skilled help to succeed.

Andreas Dörken has over 25 years of experience working in industrial firms and consulting. He began his career in the petrochemical industry (British Petroleum, PdVSA), where he re-engineered the production processes of medium and heavy oil. He then started to implement lean manufacturing best practices in various process and discrete production environments, spreading from food processing and chemical to automotive suppliers, agricultural equipment, metalworking and industrial hardware. He was CEO of a lighting equipment manufacturer, before returning to consulting. He managed local and global footprint strategy developments and deployments.

Furthermore, he co-leads the product innovation & value management practice at Argo. In that capacity he has led several long-term engagements related to value engineering and Lean Product Development in the valves, pumps, agriculture, automotive, electronic goods and chemical industries in Europe, as well as in US, and Asia. Andreas manages Argo’s European private equity portfolio, thus getting involved in numerous operations due diligences (ODD) across a wide industry spectrum every year.

Exchange

Following the spirit of Lean Product & Process Development EXCHANGE, there will be good possibilities to Exchange knowledge with other attendees as well as with the speakers.

After each presentation, we have a session +Reflections and interaction where you will reflect and interact on the learnings from the presenter.

We end the virtual LPPDE with some final reflections and remarks and hope the Exchange will continue on our LinkedIn site.

Learn!

LPPDE events have an impressive gathering of lean product and process development practitioners. We’ve assembled an impressive lineup of keynote speakers.