LPPDE Europe

Join leading thinkers pioneering lean product and process development?

April 24-26, 2023

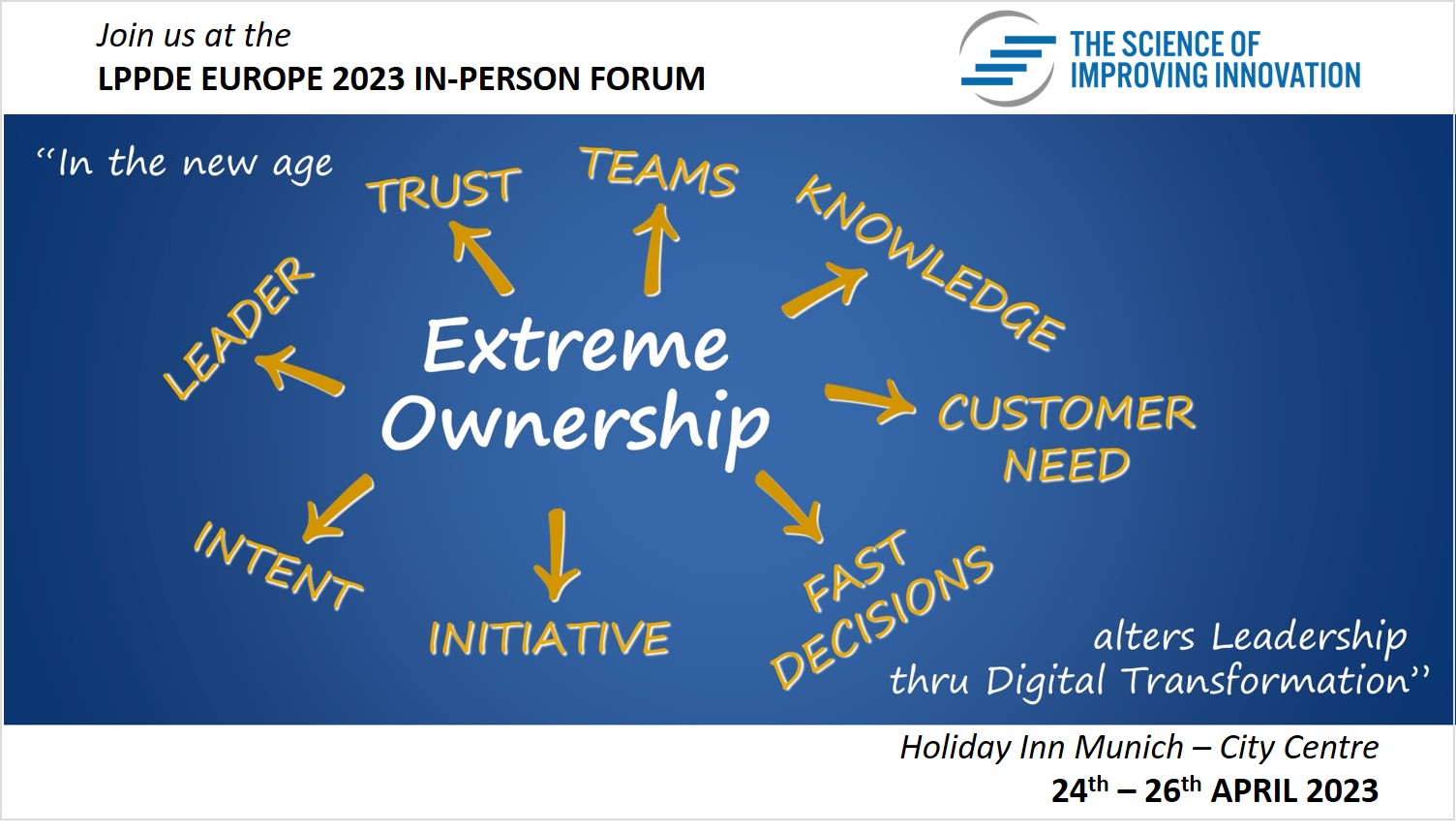

Extreme Ownership

The speed and pace of the global operating environment is only getting faster. Leaders and teams that win on any challenge, take “Extreme Ownership” of their continuous improvement while being agile. The effects of making faster decisions, based on just made learnings through customer collaborations, are both aligned to where the future unfolds and are cumulative.

Today’s fastest developing companies have taken the Lean Agile principle of “Test First” to a much higher-level, using machine learning, artificial intelligence and automated testing. Teams improving, extending or disrupting products and services don’t need to understand in advance, when they have the ability to instantly learn through many small, cheap and fast experiments. Teams are trusted, so based on their just made learnings they can make fast decisions. This embodies; looks at the future, small known errors and large positive gains (opportunities), little understanding is necessary, just rationalizing in comparing two outcomes, exercising and deploying the better option at once.

Join some of the leading practitioners in Lean Agile Digitalization and Leadership who will share, how digitization combined with servant leaders and trusted teams taking "Extreme Ownership", plays out to support teams to learn and decide quickly, and win on any challenge to satisfy their customers.

Early-bird, register and pay by February 24th:

1 person eligible for 10% off. Use discount code 1EARLY

Group of 2 persons eligible for 15% off. Use discount code 2EARLY

Group of 3 persons or more eligible for 20% off (up to €2 500 savings!). Use discount code 3EARLY

Christer Lundh

AUFERO

Conference Chair

Sponsored by:

Monday, April 24, 2023 Pre-Conference Workshops

Workshop Track 1

08:30 - 17:00

Lunch Included

The Lean Machine – The 7+1 principles of Lean Product and Process Development

Dantar Oosterwal and Andreas Dörken

Argo-Efeso Consulting Group

This workshop introduces participants to the foundational principles of lean product and process development. It is targeted specifically for newcomers to the community to help get them up to speed on some of the basic concepts so they can get the most from the main conference. The workshop based on Dantar´s model “The Lean Machine 7+1”

In 2003 Harley-Davidson was awarded the Outstanding Corporate Innovator award by the Product Development Management Association (PDMA) yet a short time later the same organization was able to deliver over 4 times as much innovation. Through a significant investment in production capacity, the backlog of motorcycle demand Harley-Davidson had enjoyed in the 1990’s drastically reduced. In order to generate product demand, Harley-Davidson adopted lean product development methods to their product development system powering this dramatic improvement in innovation output and demand. Not many people recognized the business significance of the article in the November 2005 issue of Easy Rider Magazine.

At a glance it was like every other article in every other bike magazine with a write-up on the latest products launches and the new model line-up for Harley-Davidson. After all, Easy Rider is not generally considered a scholarly journal. The headline of the article proclaimed in big bold print, “The Sleeping Giant Awakens”. The Sleeping Giant Awakens?

Harley-Davidson had seen 24 quarters of record sales and record profits. But these were bike guys and they were blown away by the torrent of new products flowing from the motor company. The largest introduction of new products they had ever seen. Harley-Davidson’s lean product development efforts resulted in 50% reduction in time to market and a 4-fold increase in throughput while maintaining a quality level of 98% repurchase intent. Later as the Vice President of Innovation for Sara Lee, Dantar once again applied these principles in leading the creation and implementation of Sara Lee’s global Innovation process resulting in 35% improvement in R&D efficiency and 5 fold increase in revenue from new products.

Over the years, Dantar has worked with numerous companies as an adviser, coach, and consultant to help them learn and implement these techniques. In his book Shingo Prize awarded book, ‘The Lean Machine’, Dantar shares the story from this product development transformation. In this session, he will share lessons from his learning journey as he tells his story of applying lean product development principles in a corporate environment that didn’t want to change. He will explore the complexities, the challenges, and the pitfalls associated with creating organizational change to improve the innovation process. He will also discuss key principles of ‘Knowledge based product development’ and how you can utilize them to improve any product development system to improve innovation flow, revenue growth, and profitability.

7 Keys to successful Lean Product Development that will be covered include:

- Manufacture customers

- Portfolio Cadence & Flow

- Set-Based

- Reusable Knowledge

- Visual Management

- Lead with Entrepreneur System Designers

- Teams of Responsible Experts

+ 1:

- Match Throughput to Business Need

These 7+1 key aspects to Lean Product Development and the all-important connection to the business are summarized in a one page document called Lean Product Development in a nutshell and can be downloaded here: https://www.developlean.com/lean-product-development-in-a-nutshell

5 Take-aways you can expect from this session:

- What Lean Product Development is and why it is sometimes referred to as Knowledge-Based or Set-Based Product Development

- The benefits of Lean Product Development for the organization

- Key aspects of Lean Product Development which can be applied to improve product development in any organization

- Why moving lean from manufacturing upstream to product development doesn’t work

- How to apply and integrate Lean Product development to an organization

In more recent time Dantar has teamed up with Andreas Dörken and developed the model even further.

Dantar Oosterwal is highly regarded as a global thought-leader in Lean Innovation & Product Development systems as well as an advisor, speaker and award-winning author. He has a passion for learning and applying lean product development systems to impact improvements of business performance. Dantar has championed many large and global operational improvement initiatives as well as developed and led Lean Innovation transformations for organizations resulting in profound improvements to both top-line revenue and bottom-line efficiency. He has been awarded the Shingo Prize for his work in Lean Innovation by the Shingo Institute, the Outstanding Corporate Innovator award from PDMA and several product patents. Dantar has served as the Global Vice President of Innovation at Sara Lee and Product Development & Product Planning Leader at Harley-Davidson Motor Company. His consulting experience spans a diversity of industries ranging from raw materials (mining and chemicals) to high-tech defense systems. Today Dantar is Sr. Vice-president at Argo.

Andreas Dörken, Sr. Vice-President has over 25 years of experience working in industrial firms and consulting. He began his career in the petrochemical industry (British Petroleum, PdVSA), where he re-engineered the production processes of medium and heavy oil. He then started to implement lean manufacturing best practices in various process and discrete production environments, spreading from food processing and chemical to automotive suppliers, agricultural equipment, metalworking and industrial hardware. He was CEO of a lighting equipment manufacturer, before returning to consulting. He managed local and global footprint strategy developments and deployments. Furthermore, he co-leads the product innovation & value management practice at Argo. In that capacity he has led several long-term engagements related to value engineering and Lean Product Development in the valves, pumps, agriculture, automotive, electronic goods and chemical industries in Europe, as well as in US, and Asia. Andreas manages Argo’s European private equity portfolio, thus getting involved in numerous operations due diligences (ODD) across a wide industry spectrum every year.

Workshop Track 2

08:30 - 12:30

Hybrid Agile & The Missing Link

Henrik Sonnenberg

Implement consulting

Agile has created great impact and engagement across many product development teams.

But Agile is introduced in many different ways, and done the wrong way, it can become overly focused on execution efficiency, roles, cadence and team events.

“Efficient development of products that customers don’t care about” - is not what we are looking for. Henrik has a long experience of the “Half Double Methodology” developed together with industry and academia, which focuses on three core elements: Impact, Flow & Leadership with much experience of what worked and what did not.

Join this workshop to explore the science of business validation & how it can be integrated into daily Agile practice.

Henrik Sonnenberg is trained as machinist, mechanical design engineer & partner at Implement Consulting Group. He has 20+ years experience creating new business across product / service & physical / digital. Impact focus towards builder team, investor team & enabling assets.

Assisting great teams to go even further. Identifying opportunity - customer problems - generating business solutions and validating Commercial/ Technical assumptions fast.

12:30

Lunch

13:30 - 17:00

What is Agile and Why it Matters

Miho Itakura

Agile Business Institute Inc

What is agile and why it matters? A case study of Toyota and other key Japanese players and their attempts to switch to agile.

This workshop introduces participants to agile thinking through case studies of Toyota and other key Japanese players and their attempts to switch to agile to gain speed and efficiency.

Miho Itakura is a clear thinking, results oriented business leader who takes action decisively as soon as the opportunity is open. She mainly works with executive led agile and digitalization transformations.

Tuesday, April 25, 2023

Conference Day - Lean Agile Digital Transformation

08:30

Summit Welcome

Christer Lundh, Conference chair, LPPDE

Christer Lundh will open the day with his vision for the conference focused on Extreme Ownership. Jocko Willink and Leif Babin´s book Extreme Ownership put the finger on the leaders’ abilities to lead their team, and with common efforts together win on any challenge. Extreme Ownership inspired us to both name, and use it as a theme for our conference. Leadership is essential for all organizations that aim for transformation in the new age of cloud, partnership, platforms, networks, ecosystems and collaboration. During the conference we will refer to and share these important insights.

We will listen practitioners from established companies, speakers with deep knowledge touching the latest findings from universities. As usual we will have a lot of time for knowledge exchange between participants and speakers during the conference.

08:40

Digitalization And Leadership Making Teams

Win On Any Challenge

Joe Justice

Agile Business Institute Inc

How do you use the advantages and possibilities that digitalization introduces?

How do you build and create winning teams?

What kind of leadership is needed to make this work?

Joe will take examples from his long and diverse career to exemplify how digitalization and leadership make teams win on any challenge.

Joe Justice is author of Scrum Master, published in 7 languages. Joe has worked with Bill Gates, the leadership team at Amazon, and operated the Agile program at Tesla for Elon Musk. Joe founded WIKISPEED which became an example of automotive design and production speed in a fun, egalitarian culture. Joe enjoys collaborating as a board member, writing, teaching, and running companies to make a good future arrive faster.

Joe works globally as an interim executive for Scrum in Hardware, bringing multinational companies twice the work in half the time. His teams have held 3 world records. He is a TEDx speaker, guest lecturer at both MIT and Oxford University in England, featured in Forbes 5 times to date including as owner of a “Company to watch” by Forbes Billionaire Club, cited in more than 5 business paperbacks and hardcovers, the subject of a Discovery Channel mini-documentary for his work creating the discipline Scrum in Hardware while working directly with the co-creator of Scrum, Dr. Jeff Sutherland.

Joe has worked with all of the top 3 military and defense contractors, autonomous and smart road technologies, ultra-lightweight structures, guest lectured at UC Berkeley, MIT, on behalf of Carnegie Melon, CU Denver, The University of Washington, spoken at Google, Microsoft, Zynga, Lockheed Martin, HP Labs, The Royal Bank of Canada, Pictet bank, and others. Joe’s work has been featured in Forbes, Harvard Business Review, CNN Money, the Discovery Channel, and others.

Platform for Lean Product

Development

Takashi Tanaka

Guest lecturer at Kyushu University

Agenda:

- Issue to start LEAN at Product development-phase

- Case at BCA (Boeing Commercial Airplane)

- Current hot topics

- CPS-Platform

- MBSE to accomplish AD (Auto driving) Level-4 & 5

- New generation of data-center

- Quantum Computing

- CPS-Platform for LPPDE

CPS is a radical change of the entire company tying together the processes and IT systems in an effective way. It is about developing a common platform using digital technology and change the structure of the company and reforming the bottleneck business at the same time.

Currently, it’s necessary to use DX (Digital transformation) for global product development. By applying Lean, DX will be easier to execute. The keys to implementing DX is that business processes, IT/ systems, and then management-related activities are being implemented in a well-balanced manner.

Takashi Tanaka has a deep understanding of a TMS (Toyota Management System) and has applied in many global manufactures such as automobile, aviation, and other industries.

He also has deep knowledge as PMO for automobile and aviation platform development. In addition, he has been working on BtoB Platform development using 5G, cloud, and AI/ML (Machine learning) to accomplish DX. He has built up experience and expertise in Quantum computing integrated with current computer.

Currently he is working developing CPS-Platform for university as a bridge to the industry. Kyushu University, Guest Lecturer. Before that Takashi has worked at Mitsubishi UFJ Research and Consulting Co., Ltd., PwC Consulting LLC (A&D - Airplane & Defense),

KPMG Consulting (Manufacturing), Dassault Systemes KK (PMO for automobile Platform development) and Toyota Engineering Co. Ltd (Applied TMS - Toyota management system).

Why Digitalization Will Kill Your Company Too

Jan Bosch

Chalmers Institute of Technology

Digitalization is very popular nowadays but there are risks. Jan will reflect on this very actual and important topic. He will use his vast knowledge to throw more light on this subject.

Jan Bosch is an executive, professor and consultant with more than 20 years experience in large scale software R&D management and business. Extensive consulting experience with Fortune 500 companies and board member & angel investor in startups. Areas of expertise include digitalization, aligning business and R&D strategy, R&D management, data-driven innovation management and software ecosystems.

11:00

Break

11:15

Town Hall – Lean Agile Digital Transformation

Joe Justice, Takashi Tanaka and Jan Bosch – Moderator: Peter Palmér

12:00

Networking Lunch

13:30

Leadership for the Digital Age

Paolo Sammicheli, Klimsoft

This talk is focused on how decisions can affect business success. With an analysis of data updated from last year's research, we will discuss the cost of change, decision latency, decision reversal, and implications on business performance. In conclusion, this talk explores how Agile and Scrum can help optimize the decision flow and support fast and effective decision-making. This talk is aimed at entrepreneurs, leaders, and managers who want to improve their decision-making ability and increase the competitiveness of their businesses. Learn how to become an Agile leader who drives business success through fast and efficient decision-making.

You will:

- Understand the cost of decisions

- Analyze the impact of decision latency in project failure.

- Discover data and evidence from studies updated last year.

- How to measure and improve decision-making.

Paolo Sammicheli is an Italian entrepreneur with +30 years of experience, International Speaker, and Author of the books "Scrum for Hardware," the first significant publication in the world on the topic, and "Scrum in AI - Artificial Intelligence Agile Development with Scrum." containing the foreword by Jeff Sutherland, co-author of Scrum and the Agile Manifesto.

Today Paolo works as an Agile Business Coach specialized in Scrum, Scrum@Scale, Kanban, Design Thinking, and Lean Startup, helping organizations uncover better ways of working.

Registered Scrum Trainer & Coach for Scrum Inc, Lean-Agile Procurement Trainer, and Management 3.0 Facilitator. Executive Certificate in Management and Leadership from MIT Sloan School of Business.

14:10

Break

14:15

Entrepreneurial System Designer

Andreas Dörken , Argo-Efeso Consulting Group

Andreas has worked closely with Dantar Oosterwal and continued to develop their Product Development model 6+1. During the latest years Agile has increased in the market and challenges the known methods in Lean Product and Process Development. Andreas will reflect on the challenges that comes with agile and how to build an even stronger system.

We will explore various aspects of LPD and Agile, such as:

- where do they say the same with different words

- where and why are they applied

- how can companies take advantage from both aspects

Andreas Dörken, Sr. Vice-President, at Argo-Efeso consulting group, has over 25 years of experience working in industrial firms and consulting. He began his career in the petrochemical industry (British Petroleum, PdVSA), where he re-engineered the production processes of medium and heavy oil. He then started to implement lean manufacturing best practices in various process and discrete production environments, spreading from food processing and chemical to automotive suppliers, agricultural equipment, metalworking and industrial hardware. He was CEO of a lighting equipment manufacturer, before returning to consulting. He managed local and global footprint strategy developments and deployments.

Furthermore, he co-leads the product innovation & value management practice at Argo. In that capacity he has led several long-term engagements related to value engineering and Lean Product Development in the valves, pumps, agriculture, automotive, electronic goods and chemical industries in Europe, as well as in US, and Asia. Andreas manages Argo’s European private equity portfolio, thus getting involved in numerous operations due diligences (ODD) across a wide industry spectrum every year.

14:55

Networking Break

15:25

How to connect strategy and operations by intrinsic Ownership

Christian Zingg, Creative Business Hacker

The presentation will be about:

- Understanding the Maslow Pyramid Model for companies

- Deep-Dive in the Challenges in the Transformation from Taylor driven Companies into Customer demand driven Companies. Typical defects and how to handle them

- Management Change - what we need from this role and why this is the hardest part

- Autonomy and alignment at the same time - an unrealistic wish, or how to reach that state

- instead of being afraid of, manage instability and use it to boost change

- How Tools and Frameworks can help and why they are not the holy grail

- How to develop a proper Working Culture and how to immediately destroy it

- New Generations - how to become attractive for new employees in times of expert shortage

Christian Zingg has always had the impulse to do things different and the vision to enable people to unleash their skills and create great customer centric products, which motivated him to completely shift his job focus in 2015. As Head of Digital Innovation Lab, the X-Lab, he had the great opportunity to make sure to have ideal working conditions for his team, and besides that learn so much about the success factors and hurdles of successfully switching to an agile mindset in big companies. What proves the effectivity of the X-Lab as a Light-tower of agile working inside the VW Group is the price "Best Digital Innovation Lab 2017".

Christian is proud to be part of this and nominated as "Top 40 under 40" for the management of this team! Meanwhile the spirit and culture of the X-Lab scaled up within RIO - as Head of Agile Mastery, together with his Team they developed a competitive software development company. Tough challenge, reflecting the traditional roots of our initiative! Before his digital journey he collected 10+ years of working experience in traditional waterfall development of OEM products in different positions with deep insights and learnings how big companies operate and how it comes to decisions.

16:05

Break

16:10

Lean as an Integrated Part of your Business System

Ingela Hofverberg , Atlas Antibodies

“Having practiced Lean for more than 15 years in different industries, countries and environments, it still strikes me how something that should be so easy and based on common sense can be so hard” comments Ingela. One of the most common mistakes in implementing Lean is that we take the copy paste approach where the methodology is taken out of its context and applied in a different one. What we should be doing is making sure we understand the problem we are trying to fix, the principles behind the method that can help us to solve the problem and then adapt the method so that it fits into the environment where we are trying to apply it. Having been in the vehicle production industry I have seen this multiple times when methods and tools are being lifted from a production environment into a service or admin environment – very seldom is this a success story. Lean cannot be implemented as a standalone structure

Ingela Hofverberg is a highly experienced, driven, and passionate leader with more than 15 years of working with business transformation. Ingela has designed and implemented management systems and structures founded on Lean principles and values in various different areas.

16:50

Networking Buffet

Wednesday, April 26, 2023

Conference Day - Lean Agile Leadership

08:30

Welcome back and reflection

Peter Palmér, Conference co-chair, LPPDE

Peter Palmér opens the second day with reflections on the learnings from the first day. As always on a Lean Project and Process Development Exchange event the learning and knowledge exchange is central. Peter will share his learnings and let the knowledge sink in through a reflection before presenting the first speaker.

08:40

Lean Leadership and the Importance of Developing

Teams of Responsible Experts

Dantar Oosterwal, Argo-Efeso Consulting Group

The presentation is centered around the lean leadership needed to create empowered teams of responsible experts with a clear focus. The way of doing this is that each team member need to be a team player – and work hard to be the best at your position.

- Organize around Product and Process technologies that are critical for the organization’s competitive advantage. Consider the Functional blocks of the organization.

- Utilize these units to develop visible, reusable knowledge according to their respective areas of expertise.

- Grow people who can generate new knowledge, apply that knowledge, and effectively communicate their knowledge across multidisciplinary teams.

Develop T-shaped experts

- For Teams with Broad understanding to understand how they fit in the whole larger picture – The company, for the project, and how they impact the customer.

- Deep understanding in their area of specialty and respected experts in their field.

Dantar Oosterwal, Sr. Vice-president at Argo-Efeso consulting group, is highly regarded as a global thought-leader in Lean Innovation & Product Development systems as well as an advisor, speaker and award-winning author. He has a passion for learning and applying lean product development systems to impact improvements of business performance. Dantar has championed many large and global operational improvement initiatives as well as developed and led Lean Innovation transformations for organizations resulting in profound improvements to both top-line revenue and bottom-line efficiency.

He has been awarded the Shingo Prize for his work in Lean Innovation by the Shingo Institute, the Outstanding Corporate Innovator award from PDMA and several product patents. Dantar has served as the Global Vice President of Innovation at Sara Lee and Product Development & Product Planning Leader at Harley-Davidson Motor Company. His consulting experience spans a diversity of industries ranging from raw materials (mining and chemicals) to high-tech defense systems.

The Culture Enabling a Transformational Leadership

Peter Palmér, Scania

We will go into the experience of how you can use the company culture to transform a profitable organization. What are the pros- and cons of the current culture when you need to make a transformation into a more effective and efficient way of working?

Peter will tell his view of the Scania Way journey improving the way of working within the company from the beginning of 1990 until today and looking towards the future.

Peter Palmér has extensive experience in lean management in both production and product development, as well as experience of leadership in other cultures. With 18 years of experience within production, engineering and quality followed by 20 years in various management positions in product development Peter has many stories to tell. Since the beginning of the 1990es he has been closely involved with the Scania Way development journey both in Sweden and South America.

He is a frequent speaker at international and national conferences on the subject of LPD and leadership. Peter has been working closely with LPPDE since the organization's start 2008 including seven years on the LPPDE board with a second period started 2023. Through LPPDE Peter has organized and chaired or co-chaired many conferences in Europe and in the US. Since the end of 2020 he runs the monthly LPPDE Virtual Summits, a four hour learning exchange with four different speakers. He is a member of various LPD-networks and has co-developed LPD training courses with Chalmers Professional Education and The KTH Royal Institute of Technology.

Change Management to Succeed with a Transformation

Maria Hansson, Volvo Cars

Volvo Cars has been on a change journey since 2017. Maria has been one of the driving forces on this journey and will reflect on the change management needed to improve an already successful company., with a large R&D organization with very experienced product developers.

Maria Hansson is a senior Change Leader targeting product development within Volvo Cars. Her main focus is directed to drive transformation in collaboration with the organization. She holds an MSc in Chemical Engineering from Chalmers University of Technology and have held a number of managerial positions within the organization over 25 years, mainly within system engineering environmental technology and powertrain controls.

11:00

Break

11:15

Town Hall – Lean Agile Digital Transformation

Dantar Oosterwal, Peter Palmér and TBA, Moderator: Christer Lundh

12:00

Networking Lunch

13:30

Why no One is Even Close to Keeping up with

the Pace of Innovation at Tesla or SpaceX

Joe Justice, Agile Business Institute Inc

Today the innovation pace Tesla and Space X is the highest in the industry. They are leading and improve faster than the competition.

Joe will go into the secrets of their way of working and share tips and tricks on what is needed for a true lean-agile transformation of a company. One being working with hypothesis and experimenting to learn fast and adjust and learn even more.

Joe Justice is author of Scrum Master, published in 7 languages. Joe has worked with Bill Gates, the leadership team at Amazon, and operated the Agile program at Tesla for Elon Musk. Joe founded WIKISPEED which became an example of automotive design and production speed in a fun, egalitarian culture. Joe enjoys collaborating as a board member, writing, teaching, and running companies to make a good future arrive faster.

Joe works globally as an interim executive for Scrum in Hardware, bringing multinational companies twice the work in half the time. His teams have held 3 world records. He is a TEDx speaker, guest lecturer at both MIT and Oxford University in England, featured in Forbes 5 times to date including as owner of a “Company to watch” by Forbes Billionaire Club, cited in more than 5 business paperbacks and hardcovers, the subject of a Discovery Channel mini-documentary for his work creating the discipline Scrum in Hardware while working directly with the co-creator of Scrum, Dr. Jeff Sutherland.

Joe has worked with all of the top 3 military and defense contractors, autonomous and smart road technologies, ultra-lightweight structures, guest lectured at UC Berkeley, MIT, on behalf of Carnegie Melon, CU Denver, The University of Washington, spoken at Google, Microsoft, Zynga, Lockheed Martin, HP Labs, The Royal Bank of Canada, Pictet bank, and others. Joe’s work has been featured in Forbes, Harvard Business Review, CNN Money, the Discovery Channel, and others.

14:10

Closing Address

Christer Lundh, Chair of the conference, LPPDE

What learnings and practices will you be taking back with you to apply on Monday morning?

14:30

Networking Break

Mini-Workshop

15:00 - 17:00

Extreme Ownership for LPPD teams

Christer Lundh, AFERO

This is a highly interactive workshop on the subject of Mission Command.

The target audience is primarily leaders driving innovation and technology development. Speed has become an increasingly important foundation for successful innovation and technology development. To achieve speed and full potential of Agile and Lean in technology development, leaders have a lot of valuable learnings to make from the leadership philosophy of Mission Command. Its origin from Auftragstaktik while proven its worth for over two centuries, it is still a modern leadership principle.

Auftragstaktik is a German expression describing a rapid military tactic, designed to dismantle enemy forces through the use of mobile forces.

Those who recognize the turbulent nature of innovation and technology development at speed, Mission Command principles provides for fast, flexible, and decisive action in a complex environment characterized by uncertainty, fluidity, and rapid change.

Leader's that apply Mission Command, informs what his/ her intention is, sets clear achievable objectives. It is the leader’s responsibility to specify the objective and the framework within which the subordinates have to accomplish the mission. The leader provides all resources required to carry out the mission. Acting based on an intent empowers subordinates’ decision-making, decentralized execution and provide room for initiatives appropriate to the situation. The planning and execution itself become the executor’s responsibility. Together the leader and their teams represent the strong bond and mutual trust, built through shared values and experiences of overcoming adversity. Hereby the whole organization attain speed and start creating outcomes beyond the means.

Successful leaders within this organization foster an environment of experimentation, mistakes and uncertainty, giving room for rapid adaptation. Since the world is fundamentally complex and uncertain, organizational change is non-linear. Mission Command enables to comprehend, shape, adapt to, and in turn be shaped by an ever-changing, uncertain and complex environment that creates mismatches and new opportunities.

Mission Command can provide the leader applying Agile and Lean for innovation and technology development the best means to succeed. As Mission Command leader you seek to exploit trust, cooperation, judgment, focus, and implicit understanding to lessen the effects of uncertainty, fluidity, and rapid change. As leader you rely on Mission Command to provide the flexibility and responsiveness to deal with uncertainty and to generate the speed which is recognized as a key element of success in innovation and technology development.

Differences in ‘Mission Command’ and ‘Command and Control,’ and reflect them in a Technology Development context will be covered.

Christer Lundh has over the past fifteen years, in different leader positions effectively implemented, and applied product development process based on Flow and Knowledge Based Development (KBD) at multiple companies.

To empower people, Christer has successfully adapted development teams around ‘Function / Value’ recognized by customers. Small interdisciplinary Function Teams, applying Cadence and Flow on two-to-three-weeks takt, using Kanban Flow Boards and Daily Stand-up. And training and mentoring leaders and engineers, on the job training, of A3 process for problem solving / gap closing.

Christer has worked in lean set-up as Entrepreneurial System Designer leading a new venture Lean start-up. With speed and focus, rapid and valuable customer feedback and great sense of urgency, the development teams swiftly improved on every new prototype. Enabled teams to learn about customers’ true needs. With servant leadership, aspirational targets and empower of people, teams quantify and make gaps visible. To see, boost motivation, and create focus. Applying homing (gap-closing), with multiple quantified countermeasures, teams together close their gaps, and the best – them owning the solutions.

At Kongsberg Automotive, Christer initiated a companywide transformation implementing Knowledge Based Development in 2008. He led that strategic transformation during 2009 working together with Michael Kennedy (TCC). Thereafter Christer led the pilots as trainer that pioneered a full global roll out during 2010-2013.

Christer, owner and consultant AUFERO AB. Embedded, as a transformational "catalyst", he offers help to leaders to succeed with Agile and Lean Product Development.

Agenda under development, minor changes pending

Register Now!

LPPDE events have an impressive gathering of lean product and process development practitioners. We’ve assembled an impressive lineup of keynote speakers.