Much is said and written about Lean and Agile transformations, yet many company transformations suffer from low effectiveness and are burdened by bureaucracy. So how do transformational leaders set out a game plan to succeed? And how do leaders actually create a highly innovative, Lean and Agile organization? Here are some personal leadership experiences on Lean transformation.

As Entrepreneurial Managing Director leading a new venture startup, I literally started the mission I’m sharing here from scratch. The vision was to create a new global business, develop a product fitted to the market, and to set up a completely new value stream. From the beginning, as part of building the team, I directly trained small teams in Lean, Agile and growth mindsets. As a startup we had to build knowledge from the bottom up including; customer value, user experiences, products development, the supply chain and manufacturing technique.

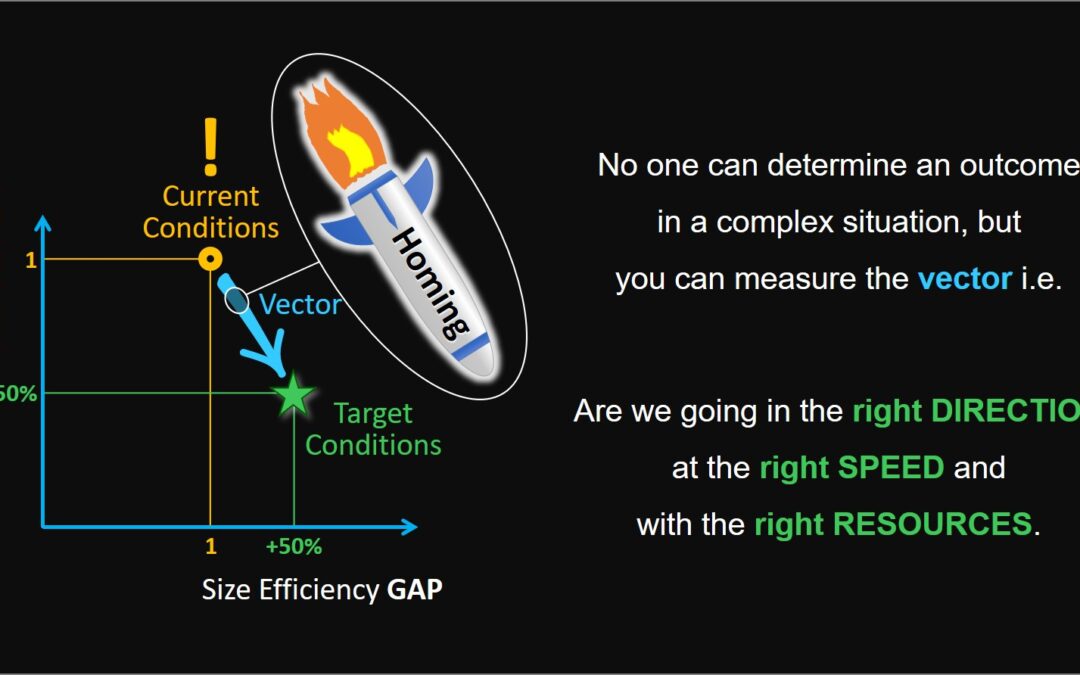

To summarize, we ran early joint testing together with customers to learn about their needs. The team built eight prototypes in just over two years. We felt our way forward. After lots of explorations, we were now ready to put ourselves in the winner’s position. Based on combined feedback, I established the aspirational target for us to develop the world's #1 most size-efficient system, and as a balance a very challenging unit cost target. With the focus on these goals, in just a few months, the combined team proved how to reach the targets. The size efficiency was improved by +50%, and the unit cost was reduced by -50%. Very impressive.

How did we succeed doing just that? What changes had we made in our work organization?

From our starting point, we had a steep learning challenge in front of us; what job to be done, customer’s true needs, what didn’t work, more “unknown unknowns” than “known unknowns,” and what not to do. Within this flat organization, for speed and to harvest opportunities, the idea was that every team would make their own plans and real-time decisions, on priorities and what was their next major problem to work on. This didn’t come easy.

The whole team cultivated close personal relationships with customers. Established customer collaborations, which provided the team with early feedback, was a crucial condition for our success.

I established daily internal communication to make everyone's energy move us in the right direction. Full transparency on challenges and opportunities. The defined direction of travel provided focus. The "why" was clear to all, and that by following the defined direction we would most certainly reach our aspirational targets. Teams applied Mission-type Tactics (a.k.a. Mission Command). This unleashed the teams' creativity, freeing them to take disciplined initiatives aligned and the overall intent, towards our common goals.

Here are some interesting approaches we refined over time. For prototyping as pre-explorations, teams ran multiple subsystem trials with “small errors.” Trials with small errors are simple experiments to build design knowledge, and avoid something that would not work in the final design. Through outcomes of these trials, we defined current conditions AND quantified the knowledge gaps against our targets, i.e. worlds #1 in size efficiency etc. If you shall cook one secret sauce from this story, is it the game changer through constantly seeking knowledge on current conditions as a precondition when building in quality. By making all gaps visible, quantifiable, teams closed 100% of all gaps by applying “target homing.”

“With joint efforts, the cross-functional team managed together to close all gaps every time, reaching all the way towards very complex targets. And the best part – they were accountable for the solutions.”

“Target homing” is a very interesting combination of the principles of Direction, Robust Problem Solving and Set Based Concurrent Engineering (SBCE). The team asks; why are we doing this, what are the current and target conditions? Then define the knowledge gap between these. And make trials with small errors, to learn what has impact as a function of the gap. The team will make a decision of which countermeasures to utilize to close the gap, by first disqualifying those having none or the least impact. Then apply a mix of countermeasures having the greatest impact. And finally, some more simple trials with small errors to show the gap is now closed. Teams improve their way of working by every gap they close.

To conclude, here are some of the most important principles we applied as a team to succeed with our transformation:

- Trials with small errors, enabled superior learning with the shortest feedback cycles at low cost. This created options. Teams kept everything that was better, and were not negatively affected by small costs of each error. In other words, small known errors and large positive gains. Ability to gain fast feedback is crucial to the success of any transformation journey.

- Robust problem-solving technique, is key for fast feedback cycles. Quantified current conditions, defined knowledge gaps against desired next target conditions, and closed gaps by deploying multiple countermeasures having impact as a function of the gap.

- Set-Based Concurrent Engineering, focused on learning outer limits and trade-offs. Collect raw data from running many fast first-principle trials with small errors. And built in quality by disqualifying the weakest solutions first, creating more options by avoiding the temptation to jump straight to the one that looks the best first.

- “Target Homing,” seeking which multiple countermeasures that have impact to close the gap to reach the target. Different, but much faster and more reliable way, to close a quantified gap (e.g. “20”), than to develop against requirements (typically “100”)

- Continuous improvement, the foundation of managing product development is continuous improvements. New methods call forth ever-changing execution. Teams anticipated their use, evaluated their influence properly and then utilized these quickly.

- Pull (opposite of Push), with entrepreneurial leadership – defined aspirational targets, the direction of travel. It was easier to measure the vector, i.e. if we were moving in the right direction, with the right speed and the right resources.

- Mission-type Tactics, the network of teams makes their own plans–mission by mission–each aligning with the direction of travel, the joint mission. This is a game changer to gain both speed and ownership.

- Cross-functional teams, were encouraged to run full feedback cycles. It enabled them to instantly reuse what was just learned and improve from there.

My success as a transformational leader was based on living with my teams; participating in their challenges, their desires, their joys and their troubles. Only in this way could I estimate the worth against the requirements on the team, build mutual trust and empower people. I enjoyed it all the way.

Questions;

How do leaders actually create a highly innovative, Lean and Agile organization?

What principles have you applied to succeed with your transformation?

Join the conversation at our LinkedIn group!

The LPPDE Conference May 5-8, 2025 in Stockholm will be exploring these ideas as well as many more and provide a forum for participants to share, learn, and collaborate with other like-minded development leaders.

Christer Lundh

Funder & Owner of AUFERO AB

Christer Lundh is president of AUFERO, a firm that makes organizations more profitable by improving product development and innovation. He is a board member at LPPDE.org. A passionate leader co-creating flow of new products and innovations together with customers.

Christer Lundh has extensive experience from leading Lean Transformations. He has a deep understanding of Lean product development. During the last fifteen years, in various leadership positions, he has effectively implemented and applied product development processes based on Flow and Knowledge Based Development (KBD) at several companies.

Christer in brief:

- Senior leader consultant.

- Led large business transformations, and business, product, process and team development for more than 25 years.

- Led a Lean start-up from start to its growth take-off.

- Works embedded, provides transformational and servant leadership to business executives and teams.