If the last five years have taught us anything, it’s that we live in a world of volatility, uncertainty, complexity, and ambiguity. At our recent European Conference in Stockholm, Peter Palmer and Bengt Johansson spoke about the Cynefin (kuh-NEH-vin) Framework. Cynefin is a sensemaking tool to help teams and organizations deal with the nature of different types of systems, in particular complex adaptive systems. Introduced by knowledge management consultant, David Snowden, the framework is well known, but it specific applications to product development is not commonly appreciated.

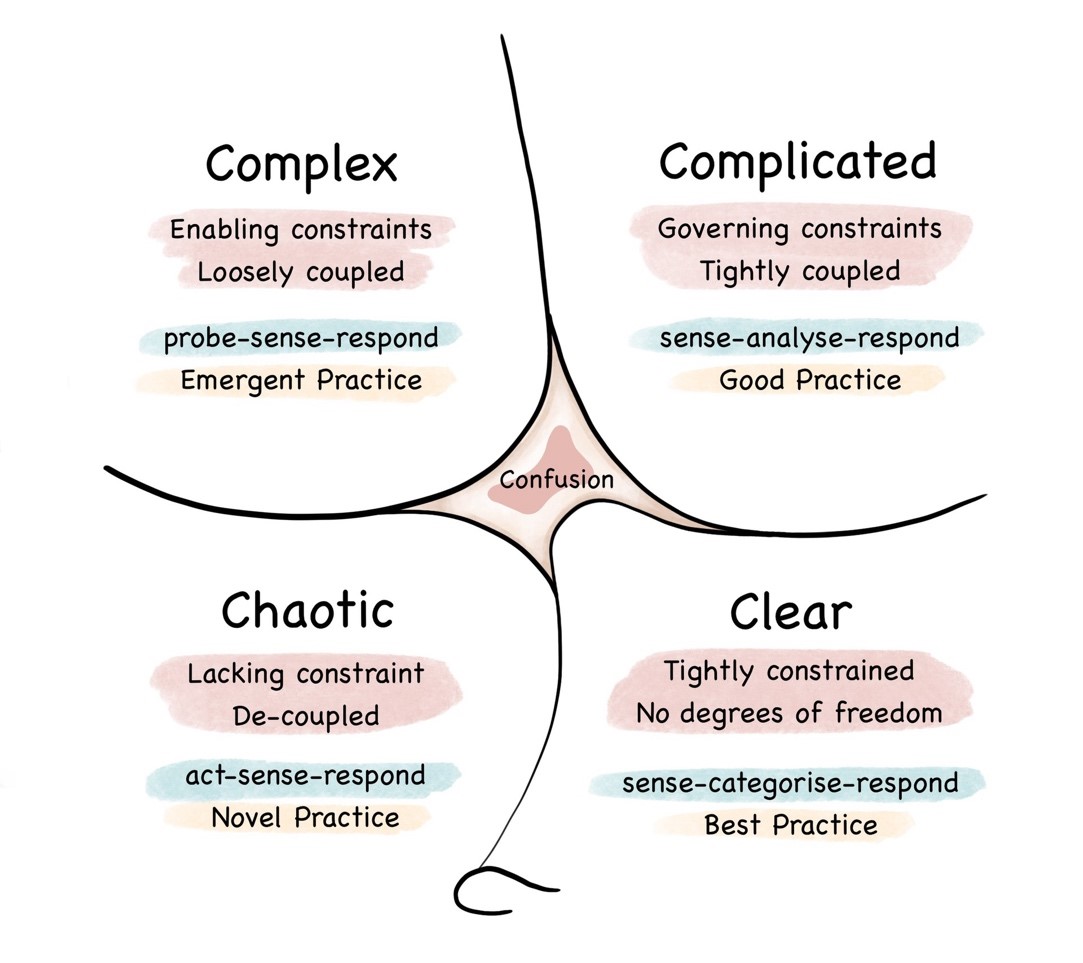

The Cynefin Framework (sketch below) consists of five domains. Confusion is the center domain, which is the state of not knowing what type of system you are in. It’s an ingenuous state, but we do find ourselves there from time to time, and risk applying the wrong approach to the situation we face.

The two domains on the right are ordered domains, where cause and effect are understood. In the Complicated Domain, experts are typical required to see those relationship, while the Clear Domain is distinct in that most causal relationships are readily apparent.

On the upper left is the Complex domain. In the Complex domain results are emergent from numerous interactions. This makes prediction impossible, but acting on the system can allow new patterns to be detected, and the results can be amplified if they are useful, dampened if not.

The lower left domain is Chaotic. In the Chaotic domain there are no constraints. In human systems, we quickly impose order and move the system to another domain.

[email protected], CC BY-SA 4.0 <https://creativecommons.org/licenses/by-sa/4.0>, via Wikimedia Commons

The Cynefin Framework is interesting enough on its own, but what does it have to do with product development? Snowden suggests that product development is the process of cycling through the domains of the framework in a clockwise fashion.

We begin in earliest product development by removing the traditional constraints on our system. We leave behind legacy designs, sometime legacy markets, and we take what Snowden calls “shallow dives into Chaos.” In the Chaos Domain, we act-sense-respond. We are running simple experiments to find the “art of the possible”. Some experiments will fail and should be dampened quickly. Others will prove interesting and merit further exploration.

This exploration is the realm of the Complex Domain, where we use abductive thinking—ideas are plausible but not verified. We probe-sense-respond with deliberate experiments to understand the limits and cause and effect relationships of our new ideas. The link between the Cynefin Framework and Set-Based Concurrent Engineering (SBCE) first emerges here: in the Complex Domain we are creating new trade-off curves to expand our design space. Done properly, the knowledge that we’re seeking is agnostic and unapplied to a specific solution. Our probes turn our abductive ideas into a design space that is ready for use through inductive reasoning.

We move from the Complex Domain to the Complicated Domain when we have the trade-off curves necessary to solve the customer’s problem. In the Complicated Domain, we sense-analyze-respond to find the precise solution within our existing base of knowledge. Not all products start with a blank sheet. Often a product refresh will be an adjustment within the existing knowledge-base or perhaps use technology that has become well understood since the original product was launched. Again, this is where the alignment between Cynefin and SBCE is helpful. If you can find solutions within the existing trade-off curves, your work does not need to leave the Complicated Domain and can move more quickly. One strength of SBCE is that it makes the transition from the Complex to the Complicated Domain explicit in the organization, with the creation of new trade-off curves.

The last domain transition is from Complicated to Clear. This is where trade-off curves have found their expression in detailed design drawings and work instructions. Entry into the Clear domain requires that decisions can be made through simple deduction within the existing, available facts, sense-categorize-respond. The Toyota Production System is the exemplar of this---if a condition is categorized as ‘not normal,’ the operator pulls the andon cord and help comes to determine the next course of action. Some engineering work is in this domain, for example, creating a specific configuration from a catalog of modules.

Different industries will experience this journey through the Cynefin domains differently. A fast-food cook lives in the Clear domain, while a skilled tradesman crosses forever between Clear and Complicated. An advertising executive lives at the boundary between Complex and Complicated—how will the audience like this idea and how many copies of the ad should we print to reach them?

Dave Snowden has said that the Clear domain is where products go to die. The risk of living too long in the Clear domain is expressed by the boundary between Clear and Chaos in the Cynefin Framework sketch. This boundary is a cliff. Falling off the cliff can take many forms: a new emerging competitor, failing to detect an internal problem, or a sudden shift in the market. An organization that allows its thinking to atrophy in the Clear domain will lose its ability to see outside the narrow confines of its existing mature products.

The Cynefin Framework can be difficult to pronounce, but understanding the concepts, and its alignment to set-based design, is useful to make sense of the inherently complex work in which we all live and work.

Questions;

Product developments, has the nature of complex systems with inherent uncertainty:

– What experiences do you have from managing complex systems?

– How can product developers apply Probe-Sense-Respond to their benefits?

– How do you as leader bring clarity, energy, and focus to even the most complex challenges?

Join the conversation at our LinkedIn group!

Andy Wagner

Boeing

Andy Wagner has been a student of aerospace production systems for his entire career, striving to understand their technical, business, and human aspects, and how the unique aerospace context influences their performance. A sponge for ideas in this domain, Andy is continually testing approaches against the lens of his current and past work to find novel and hybrid solutions to persistent problems.

-

- 8+ Years leading automation, producibility and process improvement teams and initiatives

- 12+ Years in manufacturing-technical functions, (process engineer, manufacturing engineer, and quality engineer)

- 17+ Years of collaborative Design-Build engineering experience in aerospace

- Lead, coach, and mentor continuous improvement and integration between engineering and manufacturing

- Focused on understanding problems and root causes to drive meaningful solutions