I recently returned from attending the Lean Product and Process Development Exchange (LPPDE) conference in Stockholm, Sweden. It was an excellent event with significant value for all attendees. I would like to reflect on three key takeaways from this event. For some, this may serve as a reminder or routine practice; however, for me, it reinforces our company's methodologies and encourages us to seek more opportunities to enhance our operations' efficiency and lean principles.

Firstly, Christer Lundh underscored the importance of testing early and often mitigating risk. In a traditional risk assessment, we consider the probability of risk materializing, and its impact should it occur. Christer emphasized that the probability is unchangeable; thus, our focus should be on minimizing the impact if the risk materializes. Often, we may convince ourselves that the probability of a risk diminishes over time due to experience, data, or mere wishful thinking, the latter poses a significant danger. We must avoid downplaying the probability and instead concentrate on reducing the risk's impact. Can the design be made more robust? Can it preemptively identify and counteract the risk? Allocating resources towards these areas ensures genuine risk mitigation.

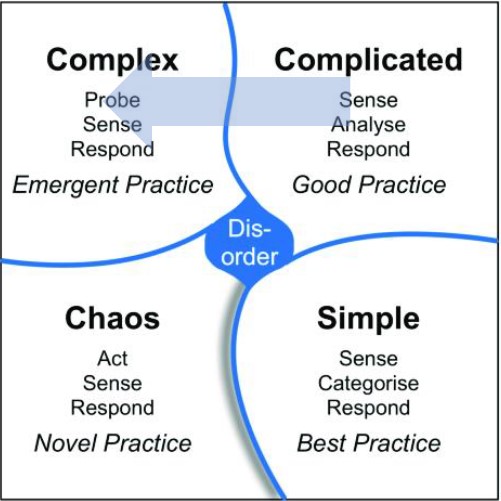

Secondly, participating in a workshop led by Peter Palmer and Bengt Johansson on Lean Product Development was highly beneficial. Despite having attended LPPDE events for many years, I continue to gain insights and inspiration from presenters and peers on enhancing our efficiency. A key point from their workshop is the shift of projects from the Complicated (upper right) to the Complex (upper left) quadrant of the Cynefin model. In Complicated projects, we can sense, analyze, and respond to project behaviors. In Complex projects, unknowns compel us to respond swiftly, necessitating probing, sensing, and responding. The objective is to develop a "sense" to acquire knowledge, which we can then analyze before deciding how to act.

Finally, Amer Catic, CEO at Yolean, discussed a feature within his tool that identifies questions requiring answers for the team to progress. In our current process, tasks are part of sprints. When a task encounters a blockage, it falls upon the responsible expert, chief engineer, or scrum master to obtain the necessary information to unblock it. We do not create a new task to gather the information nor track the time it takes to resolve the question. This process results in inefficiencies as multiple people scramble for answers, causing interruptions. Amer’s model introduces a "Question" feature in the sprint tool, assigning it to an individual who is notified electronically, and tracking it to closure. While some may view this as additional overhead, those who have experienced delays waiting for information understand the waste inherent in an open-ended system. If the tool is quick and efficient, it ensures seamless information flow from those who possess it to those who require it.

In summary, the LPPDE conference was an exceptional international event. I am already advocating for increased testing and probing to acquire the knowledge needed for informed decision-making. Additionally, my team will soon implement a "question" feature to ensure efficient knowledge transfer throughout the organization. If you have not yet joined LPPDE, I highly recommend it. You will invariably gain valuable insights that can be applied to your daily operations, incrementally advancing towards a more efficient operating model.

Questions;

How do you use reflection as a way to improve your leadership, your teams and way of working in the present?

Informed decision-making is a game-changer? In an increasingly complex world. How do you aquire the knowledge needed for informed decision-making? Advocate more testing and probing as Geoff?

Join the conversation at our LinkedIn group!

Geoff Neiley

Director CPI and CM, Rapiscan Systems

Geoff Neiley has been in the mechanical engineering field for 30 years. After graduating from the University of Maine, Orono, he learned much about the custom equipment business at NESLAB Instruments designing water chilling systems. Following this he spent 15 years working for BTU International where he designed and lead projects for conveyorized furnaces using in the electronics and solar industry. During this time, he earned his master’s in mechanical engineering at the University of Massachusetts, Lowell. It was at BTU where Geoff began to see the value of concurrent engineering. Geoff joined AS&E in 2011 where he led the mechanical team to introduce state-or-the-art x-ray products for the security market. Three years after joining AS&E (now Rapiscan Systems) in 2011, the leadership team introduced the concept of Lean Product Development. Geoff joined the leadership team reading many Lean PD books, inviting Lead PD practitioners to AS&E and attending LPPDE for several consecutive years. AS&E has roundly embraced the concurrent engineering aspects of Lean PD focusing greatly of Set-Base Innovation and cross-functional collaboration with our supply chain and manufacturing team. In 2022, Geoff took the role of Director of Continuous Product Improvement and Configuration Management. In his new role, he continues to leverage his learning from 8-years for practicing LPPD. Geoff has been a member of the board of Lean Product and Process Development Exchange since 2019. Today he is still learning and experimenting with lean processes and enjoys the pride felt in enabling a cross-functional team to achieve challenging, rewarding goals.