In the article “Unlearning What Toyota Taught Us,”1 author John McElroy lauds Tesla’s success with electric vehicles and wonders where Toyota has been. He specifically quotes the book The Toyota Product Development System2 when describing the Toyota product development standard, which he contrasts with the process used by Tesla: much more rapid improvements, no spec freeze, changes after the launch, etc. McElroy also remarks how forgiving Tesla customers are with small quality problems.

Obviously, Tesla customers appreciate their Tesla cars more than a comparable Toyota, despite the shortcomings. And Tesla has addressed many customer pain points like selling through “apple-like” stores, building super charging stations and offering their own insurance.

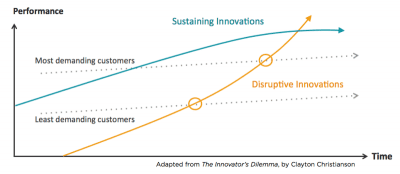

Actually what happens here is not new. It is a result of the “Innovator’s Dilemma,”3 which was first published in 1997 by Clayton Christensen. His research shows that companies that are masters at developing the right product for their current customers and even evolutionary innovations are prone to lose out on breakthrough innovations. After all, the breakthrough product often starts far below their current trajectory for goals of cost, quality, availability, etc. Traditional methods for market assessment are inadequate, and Wall Street would punish established companies for their poor results. Consequently, many well-established companies leave the breakthrough innovation to the start-ups. Of course, most start-ups fail and incumbents can learn from those lessons as we can now learn from Tesla. Large companies also count on mergers or acquisitions to get back into the game.

So, is there a lean or operational excellence tool that can help? Does Toyota have such a tool in their repertoire? Is there a lean principle to be applied?

Lean and innovation can live in perfect harmony and even provide synergy for each other.

YES, there is: a lean culture of innovation. It is primarily a lean culture – of which Toyota is still the benchmark. Lean and innovation can live in perfect harmony and even provide synergy for each other. Standards can be written that allow for experimentation and agility. Innovation can have a process, and that process helps manage the risk associated with disruptive innovation. A lean culture of innovation starts with education at all levels. This education includes research about innovation and creativity. A culture based on respect, trust, and empowerment can eliminate fear on all levels.

For Toyota it is not too late – many established companies became a victim of the innovator’s dilemma, but many have thrived. Good examples for established companies successful with disruptive innovation include AT&T, HP, Discover Financial Services, and Walmart. And I personally witnessed how companies like Goodyear and Akron Children’s Hospital transformed to a lean culture of innovation.

What do you think? Come and share your experiences on this topic and learn from others at the LPPDE Exchange in Newport, Rhode Island October 3-6. I plan to be there and look forward to the conversation!

References:

1 John McElroy, “Unlearning What Toyota Taught Us,” Wards Auto, Nov. 23, 2021. https://www.wardsauto.com/industry-news/unlearning-what-toyota-taught-us

2 James M. Morgan and Jeffrey K. Liker, The Toyota Product Development System – Integrating People, Process and Technology, Productivity Press, 2006.

3 Clayton M. Christensen, The Innovator’s Dilemma – When New Technologies Cause Great Firms to Fail, Harward Business Review Press, 1997.

Do you have ideas you would like to share concerning accelerating the learning process or aligning teams towards a common understanding? If so, it would be great to hear them or your feedback on this topic.

Norbert Majerus

Norbert Majerus Consulting

Norbert Majerus.is a highly experienced man. Beginning in 2005, Norbert implemented a principles-based lean product development process at the three global innovation centers of The Goodyear Tire & Rubber Company. For more than a decade he was Goodyear’s lean champion in research and development. Norbert has worked most of the disciplines in the Goodyear innovation centers in Luxembourg and Akron.

In 2016, his first book Lean-Driven Innovation was published. Also in 2016 the Goodyear R&D organization applied for and received the AME Excellence Award. Norbert has spoken at many conferences in the United States and other countries. Since retiring from Goodyear in 2017, he continues to share his extensive lean expertise.

Upcoming Event: LPPDE NA 2022 In-Person Conference

October 3-6, 2022 in Newport, RI

Join us to learn how you can increase your innovation speed, eliminate waste in your processes, and lead your team to new levels of productivity and pride. Meet people like yourself who are striving for innovation excellence. Learn what works for them. Share your challenges and successes. We want to exchange ideas with you, so we all learn to innovate faster.

Hear keynote from Bruce Hamilton of GBMP on “Developing your Teams to Accelerate your LPPD Innovation.” Meet Durward Sobek, co-author of the book, Lean Product and Process Development. And many others with deep expertise in lean product development. See the full program at LPPDE NA 2022.